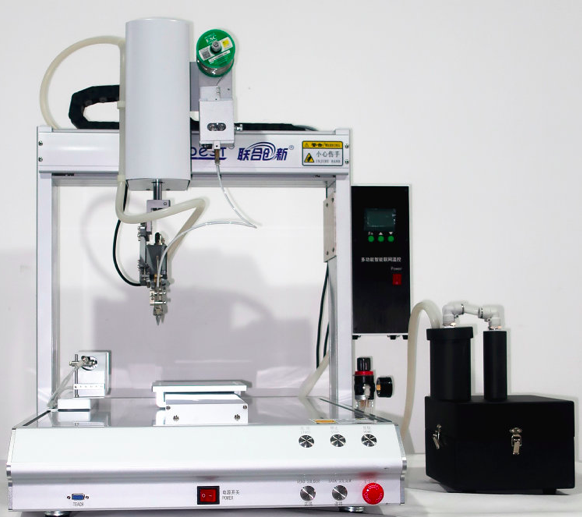

As the name implies, an automatic soldering robot is a piece of machinery that has been built and reinforced with software that allows it to perform basic and advanced soldering operations. The range of soldering robots from top brands like Topbest has been specially designed to carry out the operations which can be undergone by man – and even more.

That, on top of their cost savings, makes them a great pick.

However, some OEMs are left wondering if these robots will do the job right for them. If that is you, you have come to the right place to get your doubts lifted.

How do they work?

We won’t bother you by going into the specifics of what soldering is, or how the process works. Chances are that you have been doing that for years anyway, so it would be redundant information.

When it comes to a robotic soldering machine, though, you could be lost as to how they can perform the full range of operations that you may throw at them.

While not all of them could do the advanced things, the best ones on the market work with the following principles:

- Methods of soldering – soldering might have the same ultimate goal, but they don’t come the same. The ideal picks for you will be those options that offer the chance to execute both point and slide soldering. The machine can even be automated to choose the best mode of soldering depending on the soldering distribution under consideration.

- Z-axis rotation – when humans handle soldering, they don’t see things in 2D but 3D. The same is true for top soldering robots with a Z-axis, depending on where the solder point is located on the electrical component in question.

- Rail system – these soldering robots can handle multiple units at once, depending on the number of trails in place. Thus, one material is being soldered while the next is prepared for the operation on the rail system

- Solder tip – you must know already that there are a series of different solder heads to choose from. An ideal pick for high precision manufacturing would be the dual head solder tips. The only downside to this is that the Z-axes won’t rotate with the dual head tips.

Why They Are Worth It

We cannot talk about how much ease and simplicity a soldering robot brings to the manufacturing.

For the most part, they can help OEMs to churn out more units within a specified period without suffering a drop in quality at all. Likewise, it is possible to use up less workspace in the manufacturing area with a desktop soldering robot. They also offer improved flexibility in managing complex alloys that would have otherwise been gotten wrong by human effort.

Furthermore, robotic soldering systems have shown that it is possible to develop nano parts, conserve materials (wires, components, solder, etc.) and save costs overall while at it.

That should be enough to get you sold on the idea of these units and how they can be the game-changer for your business.

Recommendation

To make soldering work well, a high-quality soldering robot is needed. In addition to the quality factor, Topbest can provide a variety of options when we choose the automatic soldering robot. A soldering robot equipped with a camera can realize real-time monitoring of the soldering process, so that errors can be found in time to avoid the loss. Besides, a preheating platform and a nitrogen protection device can be chosen according to your own needs.

As a company with more than 20 years of professional soldering solutions, Topbest provides not only high-quality and full-featured equipment but also additional professional consulting services. Therefore, it is worth your trust.